The Art of Separation – Breakaway Couplings and Major Strategies

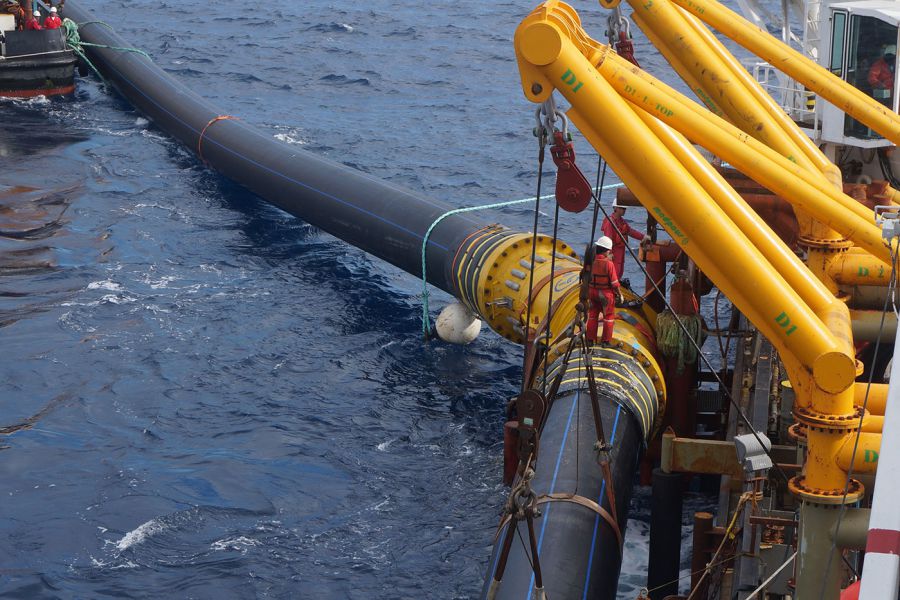

The art of separation in industrial processes involves the strategic implementation of breakaway couplings and risk mitigation strategies. Breakaway couplings are pivotal components designed to disconnect or separate sections of a system when certain predetermined conditions are met, ensuring the safety of both personnel and equipment. These couplings play a crucial role in preventing catastrophic incidents such as spills, leaks, or equipment damage. The key principle behind breakaway couplings is to isolate a section of the system in the event of excessive force, pressure, or tension, thereby averting potential disasters. One of the primary applications of breakaway couplings is in fluid transfer systems, where the sudden release of pressure or tension can pose serious threats. These couplings are meticulously engineered to withstand normal operational conditions while remaining sensitive to abnormal stress levels.

For instance, in oil and gas pipelines, breakaway coupling act as a safeguard against overpressurization or sudden shifts in fluid dynamics, triggered by factors like seismic activity or equipment malfunctions. The ability to swiftly disconnect sections of the pipeline under such circumstances is paramount to preventing environmental damage and ensuring the safety of personnel. Risk mitigation strategies associated with breakaway couplings extend beyond their mechanical design. Regular inspection, maintenance, and testing protocols are essential to ensure the reliability of these critical safety components. Monitoring for signs of wear, corrosion, or any compromise in the structural integrity of breakaway couplings is crucial for their effectiveness. Additionally, incorporating redundant safety measures, such as emergency shutdown systems and remote monitoring, adds an extra layer of protection and ensures a comprehensive approach to risk management.

For instance, in oil and gas pipelines, breakaway coupling act as a safeguard against overpressurization or sudden shifts in fluid dynamics, triggered by factors like seismic activity or equipment malfunctions. The ability to swiftly disconnect sections of the pipeline under such circumstances is paramount to preventing environmental damage and ensuring the safety of personnel. Risk mitigation strategies associated with breakaway couplings extend beyond their mechanical design. Regular inspection, maintenance, and testing protocols are essential to ensure the reliability of these critical safety components. Monitoring for signs of wear, corrosion, or any compromise in the structural integrity of breakaway couplings is crucial for their effectiveness. Additionally, incorporating redundant safety measures, such as emergency shutdown systems and remote monitoring, adds an extra layer of protection and ensures a comprehensive approach to risk management.

Moreover, the art of separation also involves considering the broader context of the industrial process. Comprehensive risk assessments, contingency planning, and employee training programs are integral components of a holistic risk mitigation strategy. Understanding the specific challenges and potential hazards associated with a given operation allows for the development of tailored safety measures, including the strategic placement of breakaway couplings within the system. In conclusion, the art of separation in industrial settings relies heavily on the implementation of breakaway couplings and complementary risk mitigation strategies. These couplings act as guardians against unforeseen events, providing a fail-safe mechanism that minimizes the impact of abnormal stress on a system. However, the effectiveness of these safety measures is contingent upon proactive maintenance, rigorous testing, and a comprehensive approach to risk management. The synergy between breakaway couplings and a well-rounded risk mitigation strategy exemplifies a commitment to operational safety and underscores the importance of anticipating and addressing potential challenges in industrial processes.